This section describes the various

types of Boilers: Fire tube boiler, Water tube boiler, Packaged boiler,

Fluidized Bed Combustion Boiler, Atmospheric Fluidized Bed Combustion

Boiler, Pressurized Fluidized Bed Combustion Boiler, Circulating

Fluidized Bed Combustion Boiler, Stoker Fired Boiler, Pulverized Fuel

Boiler, Waste Heat Boiler and Thermic Fluid Heater.

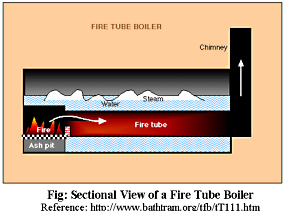

Fire Tube Boiler Fire Tube Boiler

In fire tube boiler, hot

gases pass through the tubes and boiler feed water in the shell side is

converted into steam. Fire tube boilers are generally used for

relatively small steam capacities and low to medium steam pressures. As a

guideline, fire tube boilers are competitive for steam rates up to

12,000 kg/hour and pressures up to 18 kg/cm2. Fire tube boilers are

available for operation with oil, gas or solid fuels. For economic

reasons, most fire tube boilers are nowadays of “packaged” construction

(i.e. manufacturers shop erected) for all fuels.

Water Tube Boiler

|

Fig: Simple Diagram of Water Tube Boiler

Reference: http://www.yourdictionary.com/

images/ahd/jpg/A4boiler.jpg

|

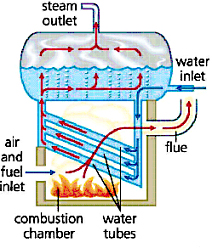

In water tube boiler,

boiler feed water flows through the tubes and enters the boiler drum.

The circulated water is heated by the combustion gases and converted

into steam at the vapour space in the drum. These boilers are selected

when the steam demand as well as steam pressure requirements are high as

in the case of process cum power boiler / power boilers.

Most modern water boiler

tube designs are within the capacity range 4,500 – 120,000 kg/hour of

steam, at very high pressures. Many water tube boilers nowadays are of

“packaged” construction if oil and /or gas are to be used as fuel. Solid

fuel fired water tube designs are available but packaged designs are

less common.

The features of water tube boilers are:

- Forced, induced and balanced draft provisions help to improve combustion efficiency.

- Less tolerance for water quality calls for water treatment plant.

- Higher thermal efficiency levels are possible

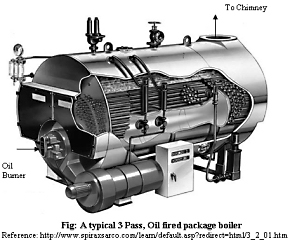

Packaged Boiler

The packaged boiler is so

called because it comes as a complete package. Once delivered to site,

it requires only the steam, water pipe work, fuel supply and electrical

connections to be made for it to become operational. Package boilers are

generally of shell type with fire tube design so as to achieve high

heat transfer rates by both radiation and convection.

The features of package boilers are: The features of package boilers are:

- Small combustion space and high heat release rate resulting in faster evaporation.

- Large number of small diameter tubes leading to good convective heat transfer.

- Forced or induced draft systems resulting in good combustion efficiency.

- Number of passes resulting in better overall heat transfer.

- Higher thermal efficiency levels compared with other boilers.

These boilers are

classified based on the number of passes - the number of times the hot

combustion gases pass through the boiler. The combustion chamber is

taken, as the first pass after which there may be one, two or three sets

of fire-tubes. The most common boiler of this class is a three-pass

unit with two sets of fire-tubes and with the exhaust gases exiting

through the rear of the boiler.

Fluidized Bed Combustion (FBC) Boiler

Fluidized bed combustion

(FBC) has emerged as a viable alternative and has significant advantages

over conventional firing system and offers multiple benefits – compact

boiler design, fuel flexibility, higher combustion efficiency and

reduced emission of noxious pollutants such as SOx and NOx. The fuels

burnt in these boilers include coal, washery rejects, rice husk, bagasse

& other agricultural wastes. The fluidized bed boilers have a wide

capacity range- 0.5 T/hr to over 100 T/hr.

When an evenly

distributed air or gas is passed upward through a finely divided bed of

solid particles such as sand supported on a fine mesh, the particles are

undisturbed at low velocity. As air velocity is gradually increased, a

stage is reached when the individual particles are suspended in the air

stream – the bed is called “fluidized”.

With further increase in

air velocity, there is bubble formation, vigorous turbulence, rapid

mixing and formation of dense defined bed surface. The bed of solid

particles exhibits the properties of a boiling liquid and assumes the

appearance of a fluid – “bubbling fluidized bed”.

If sand particles in a

fluidized state is heated to the ignition temperatures of coal, and coal

is injected continuously into the bed, the coal will burn rapidly and

bed attains a uniform temperature. The fluidized bed combustion (FBC)

takes place at about 840 OC to 950 OC. Since this temperature is much

below the ash fusion temperature, melting of ash and associated problems

are avoided.

The lower combustion

temperature is achieved because of high coefficient of heat transfer due

to rapid mixing in the fluidized bed and effective extraction of heat

from the bed through in-bed heat transfer tubes and walls of the bed.

The gas velocity is maintained between minimum fluidisation velocity and

particle entrainment velocity. This ensures stable operation of the bed

and avoids particle entrainment in the gas stream.

Atmospheric Fluidized Bed Combustion (AFBC) Boiler

Most operational boiler

of this type is of the Atmospheric Fluidized Bed Combustion. (AFBC).

This involves little more than adding a fluidized bed combustor to a

conventional shell boiler. Such systems have similarly being installed

in conjunction with conventional water tube boiler.

Coal is crushed to a size

of 1 – 10 mm depending on the rank of coal, type of fuel fed to the

combustion chamber. The atmospheric air, which acts as both the

fluidization and combustion air, is delivered at a pressure, after being

preheated by the exhaust fuel gases. The in-bed tubes carrying water

generally act as the evaporator. The gaseous products of combustion pass

over the super heater sections of the boiler flow past the economizer,

the dust collectors and the air preheater before being exhausted to

atmosphere.

Pressurized Fluidized Bed Combustion (PFBC) Boiler

In Pressurized Fluidized

Bed Combustion (PFBC) type, a compressor supplies the Forced Draft (FD)

air and the combustor is a pressure vessel. The heat release rate in the

bed is proportional to the bed pressure and hence a deep bed is used to

extract large amount of heat. This will improve the combustion

efficiency and sulphur dioxide absorption in the bed. The steam is

generated in the two tube bundles, one in the bed and one above it. Hot

flue gases drive a power generating gas turbine. The PFBC system can be

used for cogeneration (steam and electricity) or combined cycle power  generation.

The combined cycle operation (gas turbine & steam turbine) improves

the overall conversion efficiency by 5 to 8%. generation.

The combined cycle operation (gas turbine & steam turbine) improves

the overall conversion efficiency by 5 to 8%.

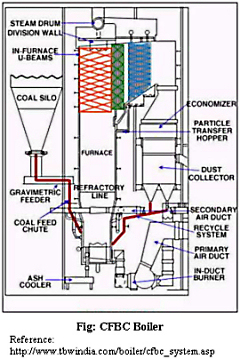

Atmospheric Circulating Fluidized Bed Combustion Boilers (CFBC)

In a circulating system

the bed parameters are so maintained as to promote solids elutriation

from the bed. They are lifted in a relatively dilute phase in a solids

riser, and a down-comer with a cyclone provides a return path for the

solids. There are no steam generation tubes immersed in the bed.

Generation and super heating of steam takes place in the convection

section, water walls, at the exit of the riser.

CFBC boilers are

generally more economical than AFBC boilers for industrial application

requiring more than 75 – 100 T/hr of steam. For large units, the taller

furnace characteristics of CFBC boilers offers better space utilization,

greater fuel particle and sorbent residence time for efficient

combustion and SO2 capture, and easier application of staged combustion

techniques for NOx control than AFBC steam generators.

Stoker Fired Boilers

Stokers are classified

according to the method of feeding fuel to the furnace and by the type

of grate. The main classifications are spreader stoker and chain-gate or

traveling-gate stoker.

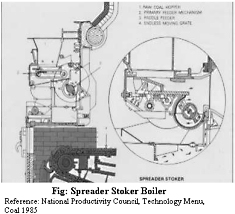

Spreader Stokers Spreader Stokers

Spreader stokers utilize a

combination of suspension burning and grate burning. The coal is

continually fed into the furnace above a burning bed of coal. The coal

fines are burned in suspension; the larger particles fall to the grate,

where they are burned in a thin, fast-burning coal bed. This method of

firing provides good flexibility to meet load fluctuations, since

ignition is almost instantaneous when firing rate is increased. Due to

this, the spreader stoker is favored over other types of stokers in many

industrial applications.

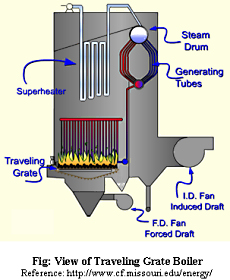

Chain-grate or Traveling-grate Stoker

Coal is fed onto one end

of a moving steel grate. As grate moves along the length of the furnace,

the coal burns before dropping off at the end as ash. Some degree of

skill is required, particularly when setting up the grate, air dampers

and baffles, to  ensure clean combustion leaving the minimum of unburnt carbon in the ash. ensure clean combustion leaving the minimum of unburnt carbon in the ash.

The coal-feed hopper runs

along the entire coal-feed end of the furnace. A coal gate is used to

control the rate at which coal is fed into the furnace by controlling

the thickness of the fuel bed. Coal must be uniform in size as large

lumps will not burn out completely by the time they reach the end of the

grate.

Pulverized Fuel Boiler

Most coal-fired power

station boilers use pulverized coal, and many of the larger industrial

water-tube boilers also use this pulverized fuel. This technology is

well developed, and there are thousands of units around the world,

accounting for well over 90% of coal-fired capacity.

The coal is ground

(pulverized) to a fine powder, so that less than 2% is +300 micro meter

(μm) and 70-75% is below 75 microns, for a bituminous coal. It should be

noted that too fine a powder is wasteful of grinding mill power. On the

other hand, too coarse a powder does not burn completely in the

combustion chamber and results in higher unburnt losses.

The

pulverized coal is blown with part of the combustion air into the

boiler plant through a series of burner nozzles. Secondary and tertiary

air may also be added. Combustion takes place at temperatures from

1300-1700°C, depending largely on coal grade. Particle residence time in

the boiler is typically 2 to 5 seconds, and the particles must be small

enough for complete combustion to have taken place during this time. The

pulverized coal is blown with part of the combustion air into the

boiler plant through a series of burner nozzles. Secondary and tertiary

air may also be added. Combustion takes place at temperatures from

1300-1700°C, depending largely on coal grade. Particle residence time in

the boiler is typically 2 to 5 seconds, and the particles must be small

enough for complete combustion to have taken place during this time.

This system has many

advantages such as ability to fire varying quality of coal, quick

responses to changes in load, use of high pre-heat air temperatures etc.

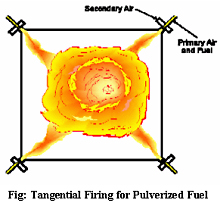

One of the most popular

systems for firing pulverized coal is the tangential firing using four

burners corner to corner to create a fireball at the center of the

furnace.

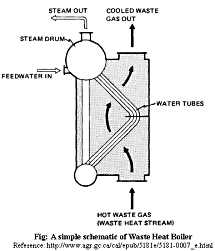

Waste Heat Boiler

Wherever

the waste heat is available at medium or high temperatures, a waste

heat boiler can be installed economically. Wherever the steam demand is

more than the steam generated during waste heat, auxiliary fuel burners

are also used. If there is no direct use of steam, the steam may be let

down in a steam turbine-generator set and power produced from it. It is

widely used in the heat recovery from exhaust gases from gas turbines

and diesel engines. Wherever

the waste heat is available at medium or high temperatures, a waste

heat boiler can be installed economically. Wherever the steam demand is

more than the steam generated during waste heat, auxiliary fuel burners

are also used. If there is no direct use of steam, the steam may be let

down in a steam turbine-generator set and power produced from it. It is

widely used in the heat recovery from exhaust gases from gas turbines

and diesel engines.

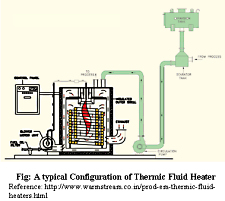

Thermic Fluid Heater

In recent times, thermic

fluid heaters have found wide application for indirect process heating.

Employing petroleum - based fluids as the heat transfer medium, these

heaters provide constantly maintainable temperatures for the user

equipment. The combustion system comprises of a fixed grate with

mechanical draft arrangements.

The modern oil fired

thermic fluid heater consists of a double coil, three pass construction

and fitted with modulated pressure jet system. The thermic fluid, which

acts as a heat carrier, is heated up in the heater and circulated

through the user equipment. There it transfers heat for the process

through a heat exchanger and the fluid is then returned to the heater.

The flow of thermic fluid at the user end is controlled by a

pneumatically operated  control

valve, based on the operating temperature. The heater operates on low

or high fire depending on the return oil temperature, which varies with

the system load control

valve, based on the operating temperature. The heater operates on low

or high fire depending on the return oil temperature, which varies with

the system load

The advantages of these heaters are:

- Closed cycle operation with minimum losses as compared to steam boilers.

- Non-Pressurized system operation even

for temperatures around 250 0c as against 40 kg/cm2 steam pressure

requirement in a similar steam system.

- Automatic control settings, which offer operational flexibility.

- Good thermal efficiencies as losses

due to blow down, condensate drain and flash steam do not exist in a

thermic fluid heater system.

The overall economics of

the thermic fluid heater will depend upon the specific application and

reference basis. Coal fired thermic fluid heaters with a thermal

efficiency range of 55-65% may compare favorably with most boilers.

Incorporation of heat recovery devices in the flue gas path enhances the

thermal efficiency levels further.

To top |